Logs 6 & 7 were put through the saw and yielded 2 off 8" x 8" x 8ft posts ready for incorpration into a local building. Local produce for local projects.

addendum - Jul 2021

Nick Dunthorne completed his Berkshire home office building incorporating the two Douglas Fir posts (seen on the extreme left).

This building demonstrates that timber buildings can be truly beautiful.

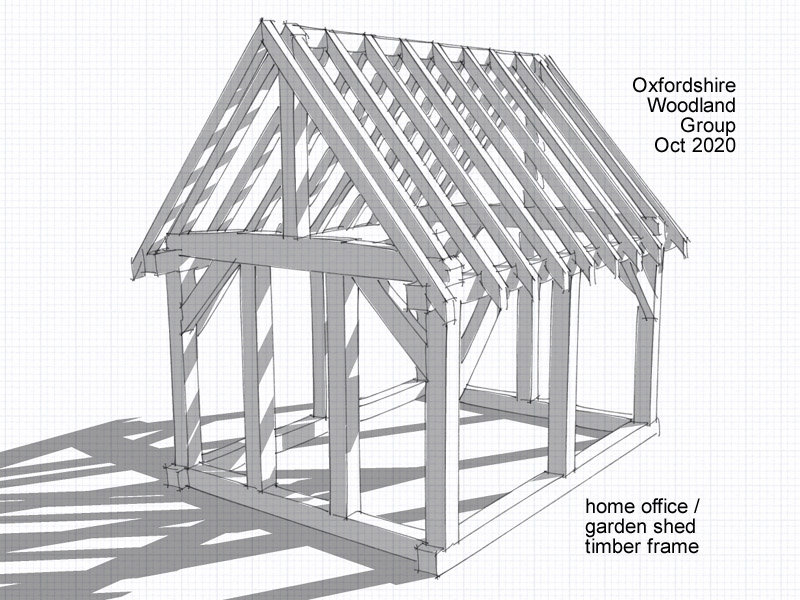

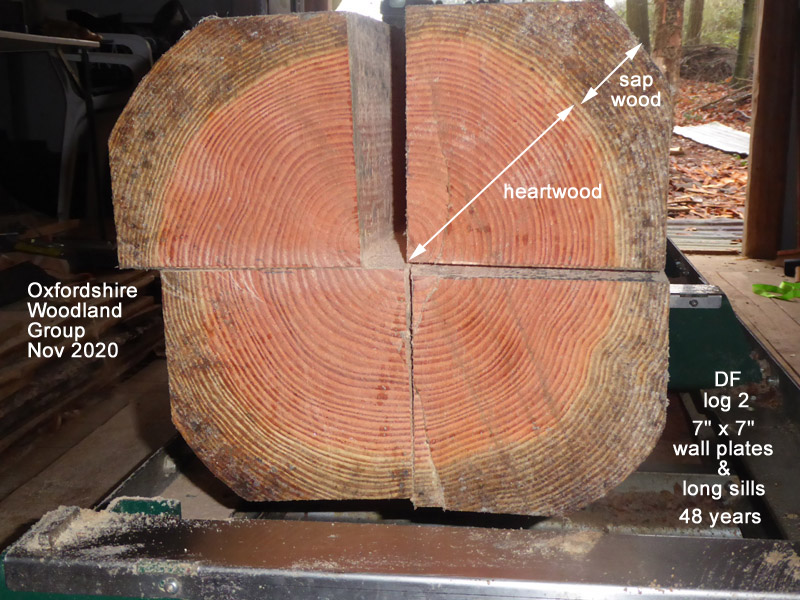

Log 3 was quarter sawn to produce 4 off 6" x 6" x 7ft sidewall & door posts for the local home garden office.

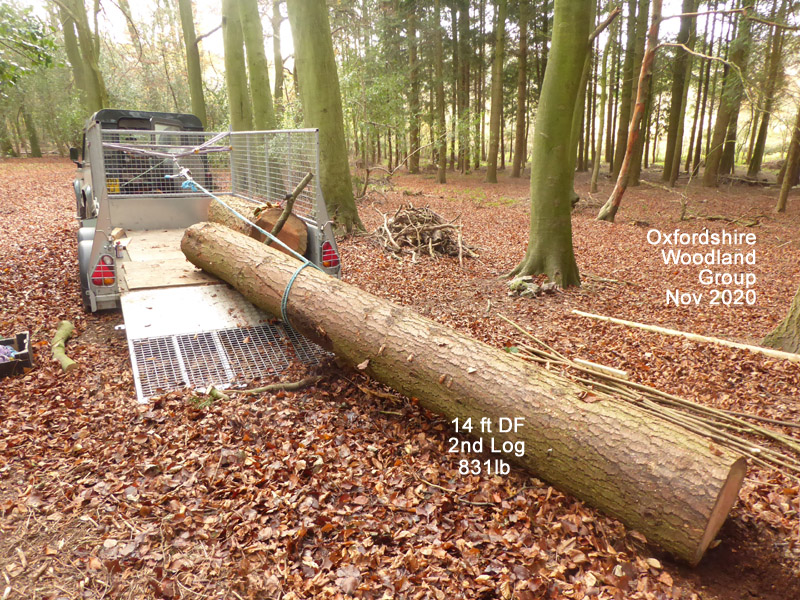

Log 4 is 12" longer than the saw head can travel and so the last 12" had to be rip sawn using a 2 man (cross cut) saw. Not ideal. This log will be used to make 2 off x 7" x 7" x 11ft cross sills for the local home garden office. We need a longer sawbed !

Log 4 is 12" longer than the saw head travel and so the last 12" had to be rip sawn using a 2 man (cross cut) saw. Not ideal. This log will be used to make 2 off x 7" x 7" x 11ft cross sills for a local home garden office. We need a longer sawbed !

OWG Fellow Andrew Jarvis fitted a 6ft extension to the sawmill bed but the end of this stuck outside the barn. We need a bigger barn !

Following the fitting of the sawbed extension we converted log 5 to form 2 matching tie beams. Each end of the tie beams will be taper profiled.

|

Author

Author Douglas Fir - One Tree project

Douglas Fir - One Tree project