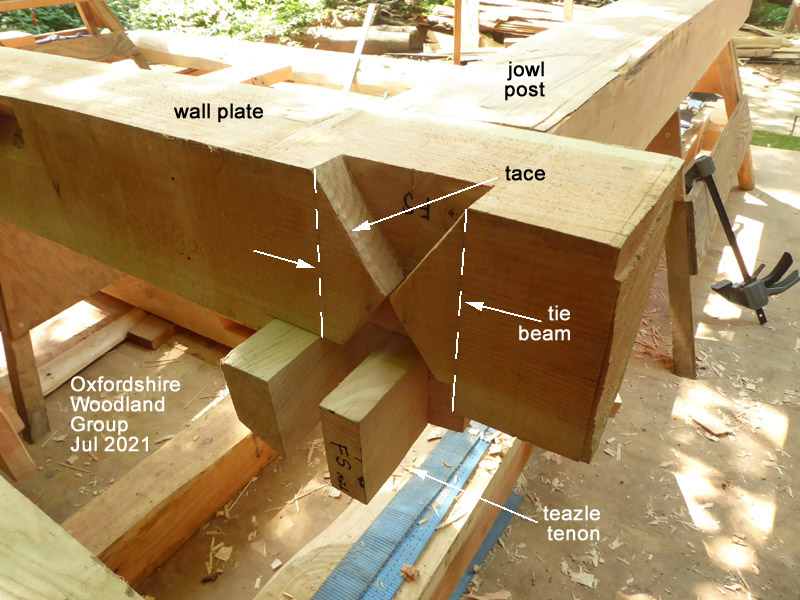

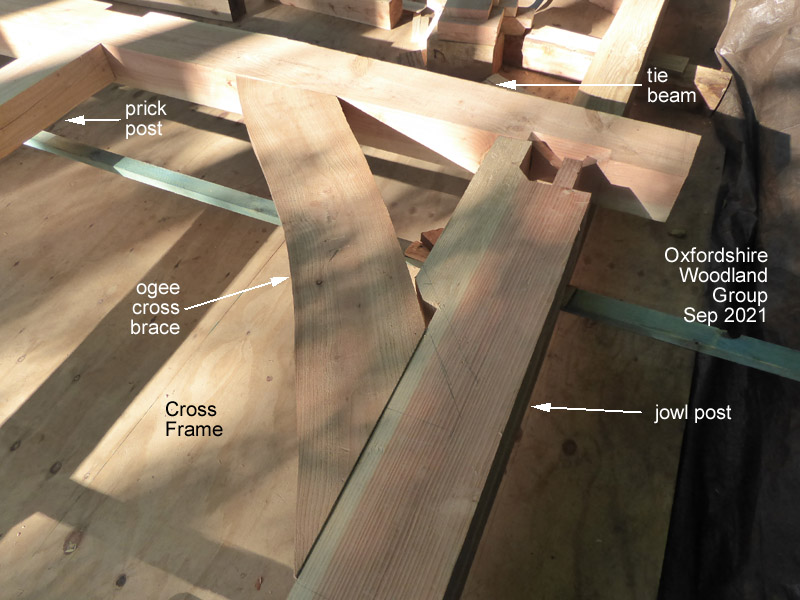

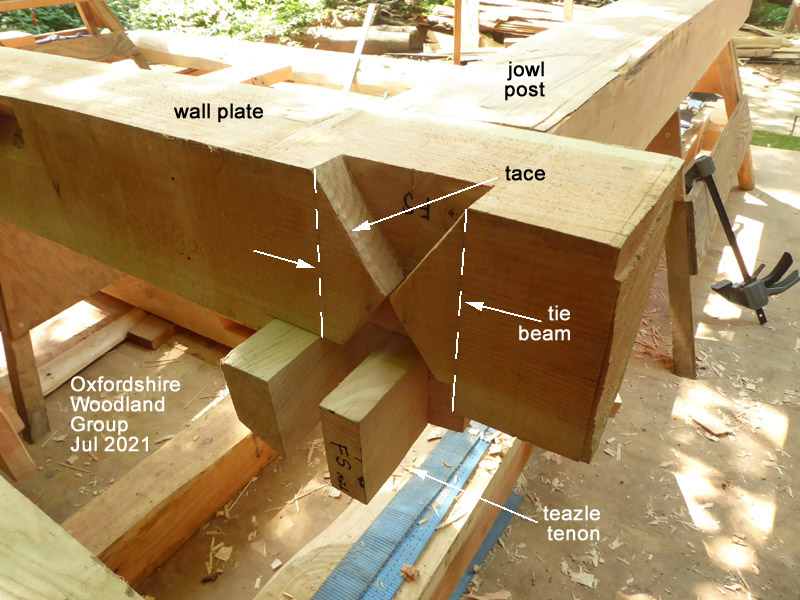

The jowl posts have now been double cut and fitted to ensure perfect alignment between the face of the #tace and the top of the #jowlpost shoulder to ensure a proper level seating for the tie beam.

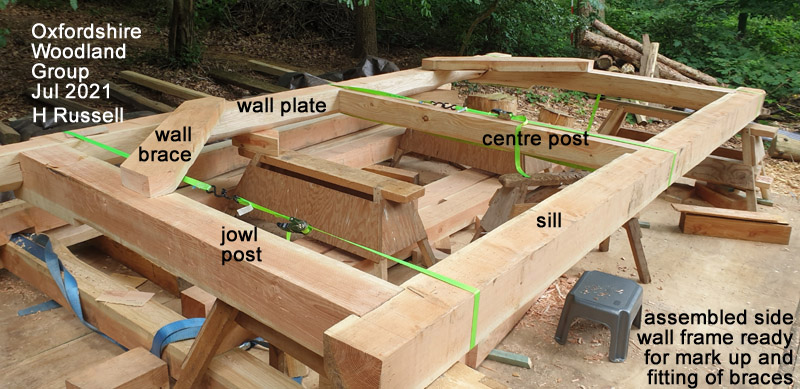

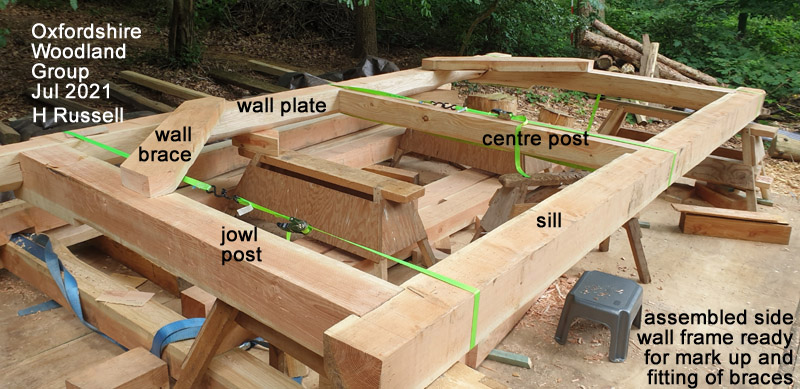

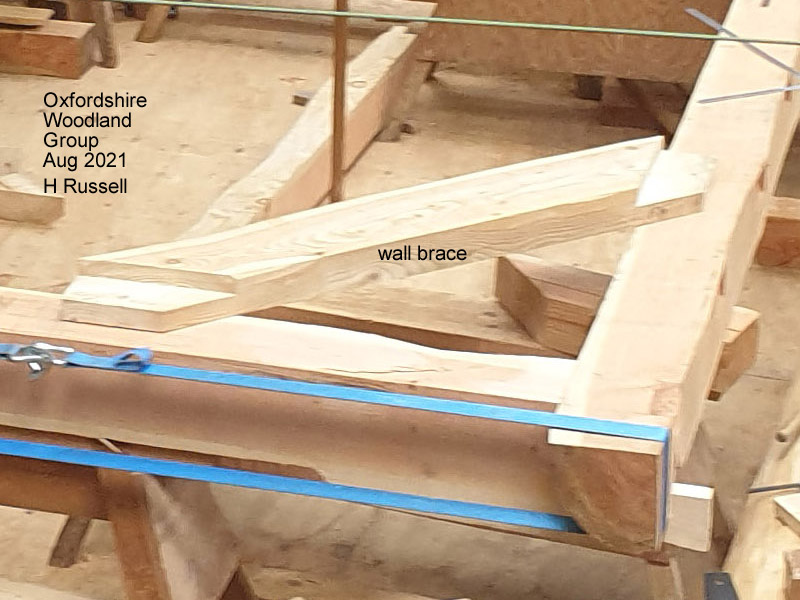

The sills have been fitted to the post bottoms and then the centre post scribed and fitted between wall plate & sill. The wall braces have been laid out marked and cut to size ready for fitting to the wall plate and posts.

The braces were cut and fitted and then the side wall frame was pulled together and checked for square. Perfect !

Sidewall frame #1 was taken apart and stacked.

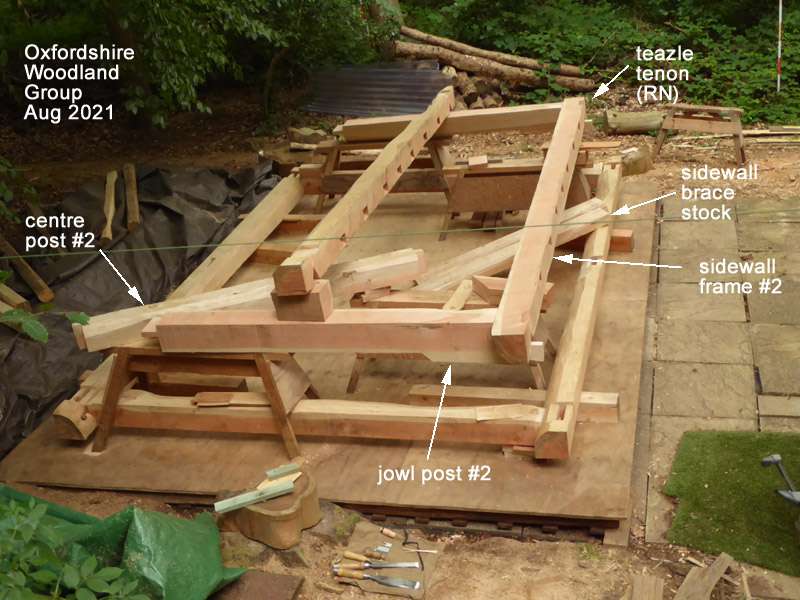

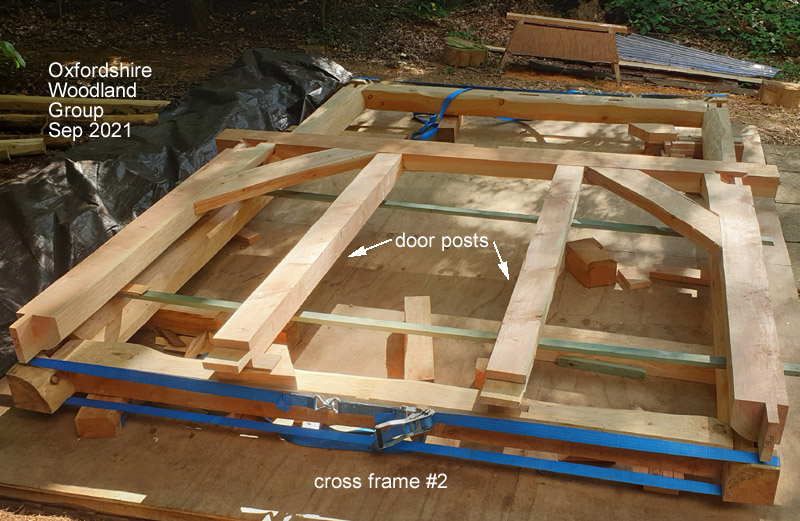

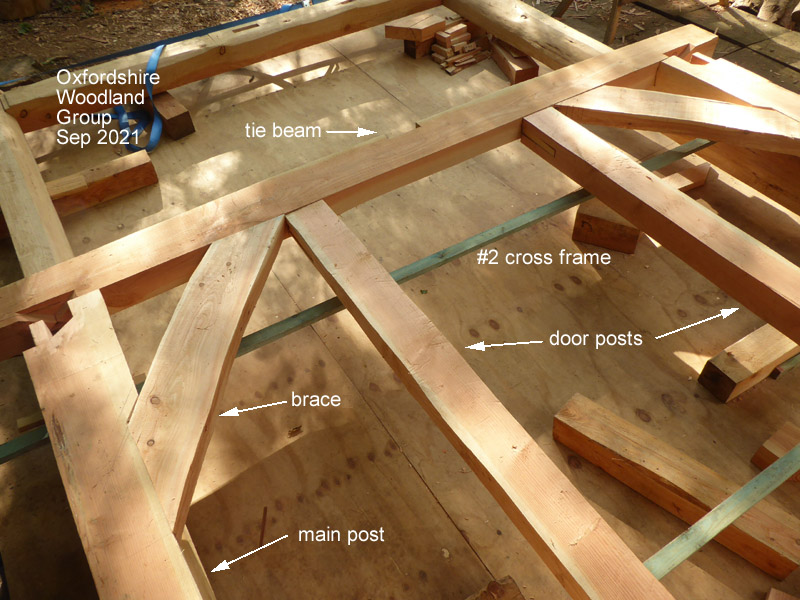

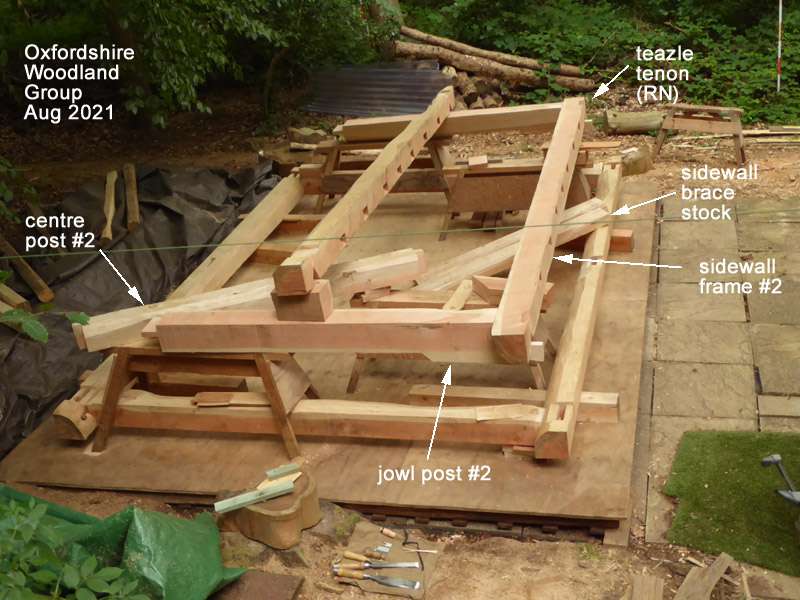

Sidewall frame #2 was then set up to scribe and fit braces and centre post.

The geometric complexity of the tace and teazle tenon of tying joint (RN) is now clear. Shame that this will shortly be concealed.

Sidewall #2 post feet were double cut, then the frame was squared and the braces were marked out and cut ready for fitting once the mortices to accept same have been cut into the wall posts & plate.

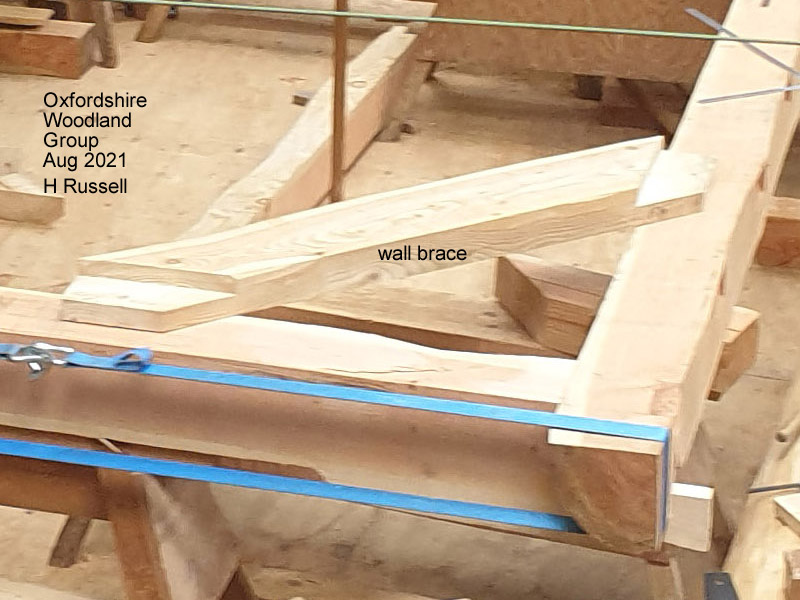

The brace stock was fashioned into 2 sidewall braces, cut to size with bare faced tenons ready for fitting into the wall post and plate mortices.

|

Author

Author Re: One Tree Timber-Frame Project

Re: One Tree Timber-Frame Project