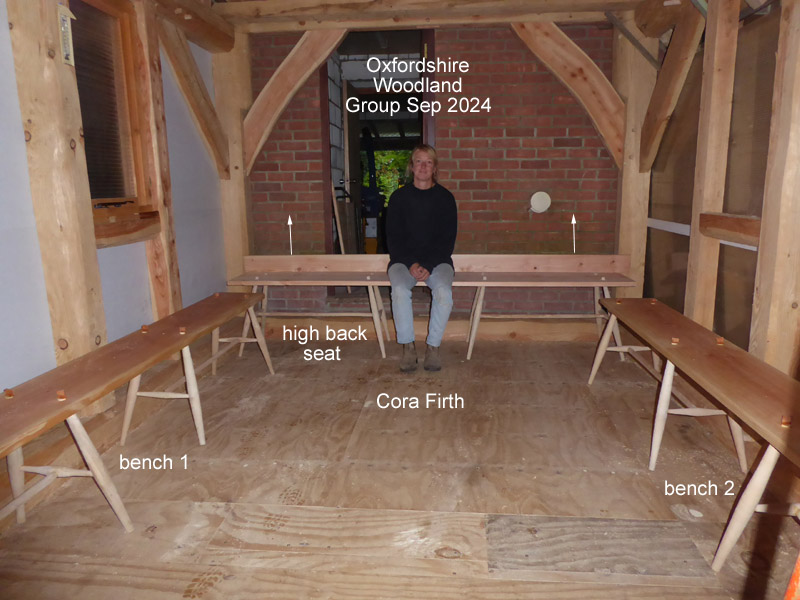

Oxfordshire Woodland Group Fellow Cora Firth was chosen to make the two Shaker benches and high back seat.

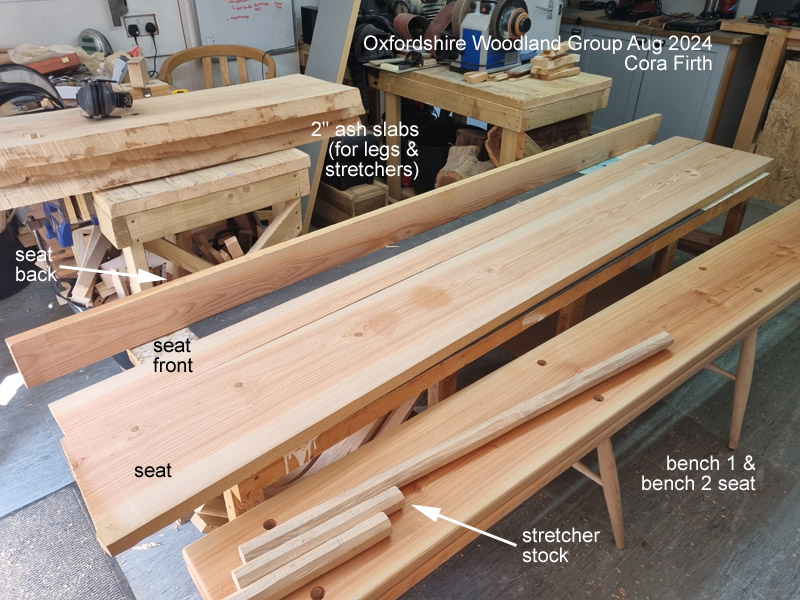

An ash tree that had been cut down in the woodland was cut into 2" thick slabs x 4 ft long and laid in stick in the barn to season.

These slabs were resawn to produce 2" x 2" and 1" x 1" stock to make legs, stretchers & rods.

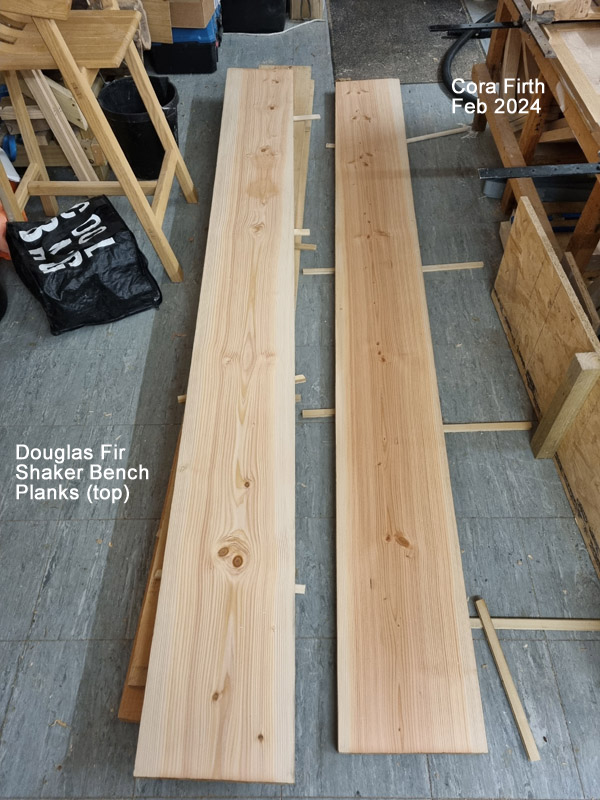

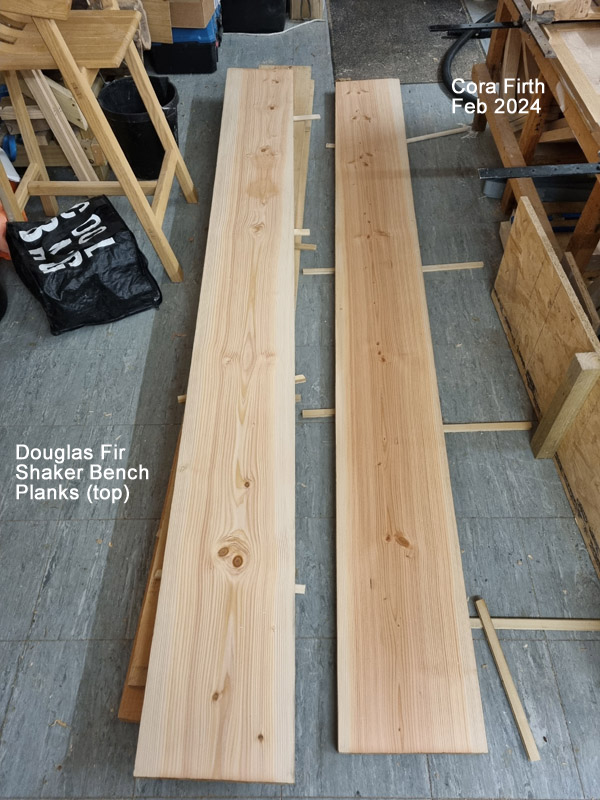

Four x 1.5" thick x 9Ft long top quality Douglas fir planks converted from a butt log and laid in stick were selected to make the seats.

These planks were sawn thru & thru from the same virtually knot free log in a manner typically found in original Shaker furniture.

The DF planks were delivered to Cora Firth's furniture workshop where they were put through a thicknesser / planner.

This process resulted in a higher contrast between knots and wood with the knotier side being relegated to the underside of the benches.

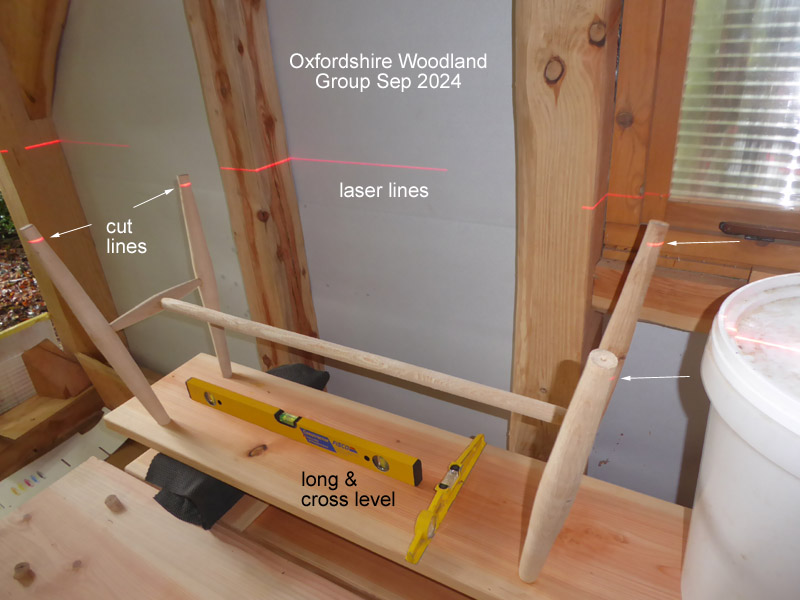

Cora Firth then prepared dry ash stock [square to octagonal section] to make both Shaker bench and high back chair legs.

The first turned legs are very appealing revealing beautiful grain patterns and colour.

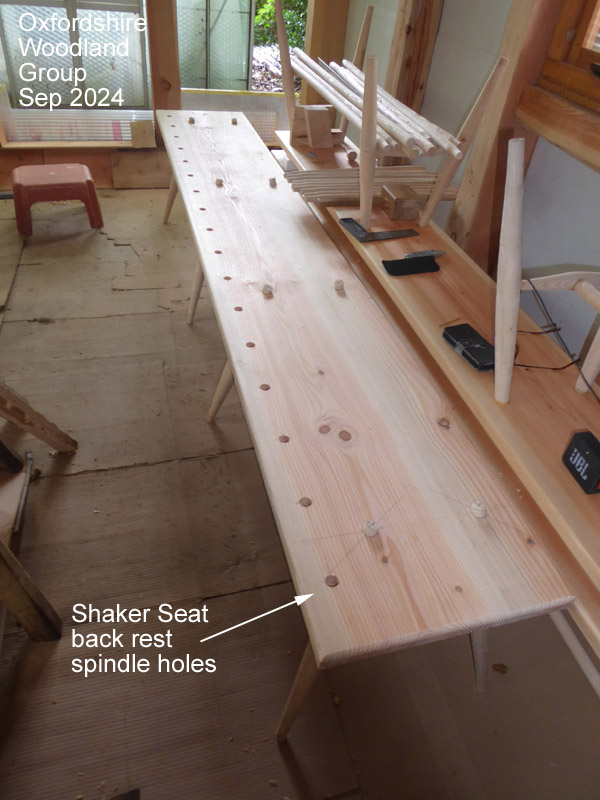

The Shaker bench seats components were delivered and assembled by Cora Firth and The Stratfield Saye bodgers at their annual week long gathering in North Hampshire (19th - 23rd August 2024).

The bench seat planks were made using high quality Douglas Fir converted by OWG to produce mirror image match marked planks

The pair of benches will be used to support attendees at OWG woodland school session.

Cora Firth and OWG Trustees were able to benefit from the Stratfield Saye chair bodgers experience in assembly and final fit of leg stretchers.

The OWG bench and high back seat designs were based on visits made to Hancock Shaker village, Mass., followed by a stay at Enfield Shaker village, NH. The care and attention invested by the Shakers in their workmanship was obvious. The Shaker's were known to say -

"tis a gift to be simple" and "hands to work - hearts to God".

|

Author

Author Shaker style benches & seats

Shaker style benches & seats