The ideal material to make shingles or shakes from is Western Red Cedar since this has only about 10 rings of sapwood (non durable) with the heartwood being durable. Other woods can and were used such as European larch.

Making shakes (big shingles) creates an awful lot of sappy slabwood which during the sawmilling process was simply criss cross stacked to dry. This should make good quick burning firewood.

The little trailer holds about 8 cu ft (0.25 cu M) of cut up firewood.

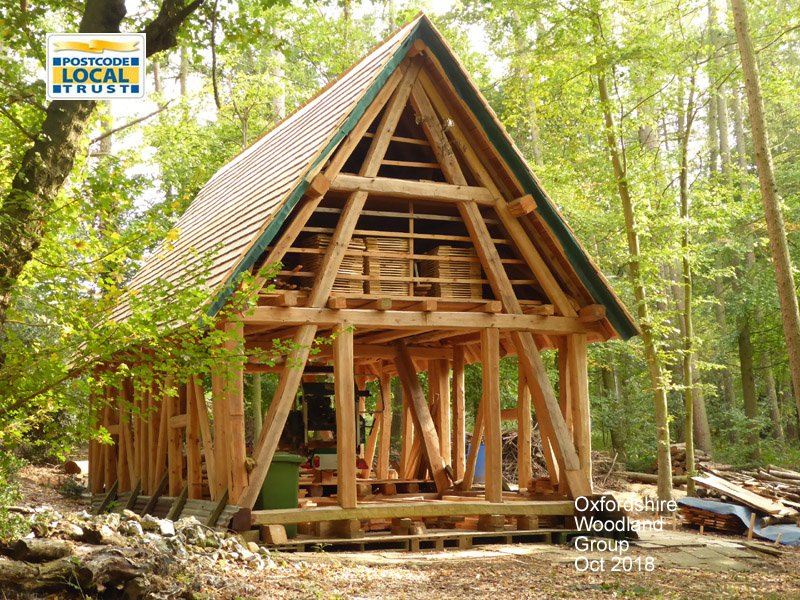

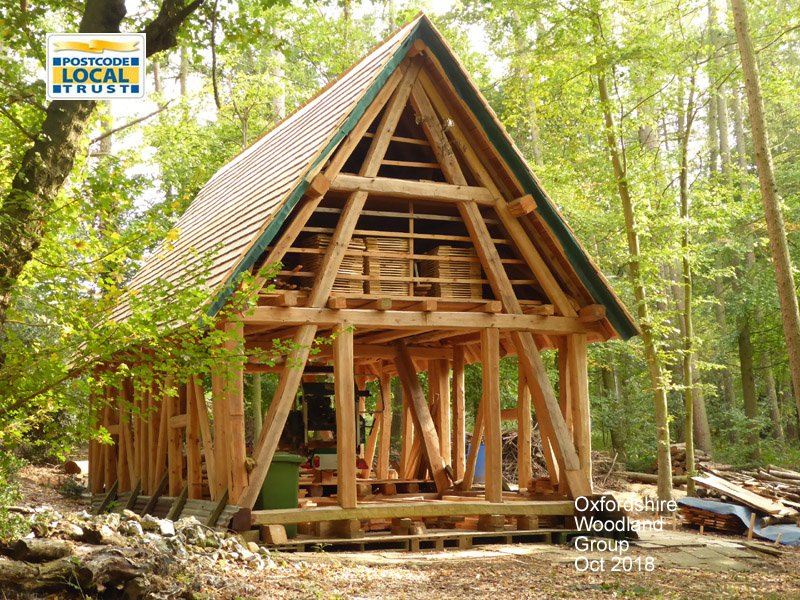

The common rafter roof was protected with a temporary heavy duty tarpaulin cover to create a weather resistant space under which shingles could be made and stored to dry and season before being used to cover the roof.

The OWG Fellows and Trustees made shingles to cover the roof using European Larch and Western Red cedar on a mobile sawmill. These are then stacked to dry, season and shrink before being fitted to the roof.

Sarking boards are fixed to the rafters followed by stapling a breatheable membrane before nailing the shingles to the south roof up to purlin level. That's nearly 500 shingles. Only another 2000 to completely cover the roof !

The south roof slope was completely covered with shingles before commencing work on the north roof slope.

This shot of the west gable and completed shingle roof was taken in the late afternoon sunshine before the cruck frame is clad with feather edged planks. It's a shame that this work of art needs to be covered up but sooner or later this has to be done.

|

Author

Author Making & Fixing Shingles

Making & Fixing Shingles